Extension module

Accessory for the AMAi, AMAi catering station

Stretch AMAi to your liking with the extension module. By adding an extra A-frame, footrest, top tube and tabletop to your existing table you can extend AMAi with electrification up to 4 modules and AMAi without electrification into infinity. Opt for the same colors and materials for the frames or get creative by combining different styles. Different tabletops are available according to indoor or outdoor use.

Materials

Structured powder coated stainless steel

Powder coating is a technique of applying dry paint to a part. The powdered paint is electrostatically charged and sprayed onto the object. The object is then placed in an oven and the powder particles melt and coalesce to form a continuous film.

Choose wisely

Choose white powder coating, only if you are willing to clean the surface regularly. There is nothing uglier than a dirty piece of design furniture, right?

How to treat powder coated materials

Click here

Galvanized steel

Galvanization is the most durable method for protecting metal from rusting. The metal is immersed in a zinc bath, which results in a protective layer. If the layer gets damaged, the metal under it will start rusting. However, any damage can be touched up with zinc paint available from any DIY store. Galvanized steel has a very long life span and is perfectly recyclable if necessary.

Choose wisely

We call it the George Clooney of coating techniques: its looks improve better with age... Our tools with galvanized surfaces are masters of camouflaging dirt, thanks to the material's rough texture. At first, galvanized pieces look very shiny, but they will gradually turn matte under the influence of sun and rain. Rain may also cause dark stains underneath the connection zones.

How to treat galvanized steel

Click here

Structured powder coated ZnAlMg steel

ZnAlMg-dipping is an alternative to hot dip galvanisation and is the best choice for more detailed products that need to be coated afterwards. Thanks to its unique composition, ZnAlMg provides high level of surface and cut-edge protection, even in the most hostile environments. It is produced on a classic hot dip galvanising line which molten bath has a unique chemical composition including zinc, aluminium, and magnesium, the perfect base layer for powder coatings.

Choose wisely

Choose white powder-coating, only if you are willing to clean the surface regularly. There is nothing uglier than a dirty piece of design furniture, right?

How to treat powder coated materials

Click here

Hellwood-PEFC

Extremis Hellwood is European Ash wood that has been through purgatory to steel it against all kinds of hellish ordeals. And there are more than enough of them out there: UV rays, rain and acid rain, fluctuating humidity levels, frost, extreme heat and so on. Our preservation gives the fibres greater internal stability and increases their resistance to rotting. In this way, we obtain a type of wood that belongs in Durability Class I, just like the very best tropical wood. An attractive side-effect of the process, of course, is the wood’s dark coloring.

Choose wisely

Just like other types of wood, Hellwood will gradually become rougher and start to turn grey as a consequence of exposure to the sun and rain. Small cracks and crevices can also appear as part of this process. We strongly advise everyone to treat the furniture with our Wood Protector. This 100% natural oil controls the moisture level within the wood, which makes the planks stay stable for longer, and the layer of oil also helps to prevent spilled liquids from being absorbed, so that stains tend to stay superficial. It is best to repeat this treatment at regular intervals.

How to treat wood

Click here

Structured powder coated aluminium

Powder coating is a technique of applying dry paint to a part. The powdered paint is electrostatically charged and sprayed onto the object. The object is then placed in an oven and the powder particles melt and coalesce to form a continuous film. The fine textured powder coating has a high scratch resistance, perfect for intensive use.

Choose wisely

Choose white powder coating, only if you are willing to clean the surface regularly. There is nothing uglier than a dirty piece of design furniture, right? TIP: our furniture with galvanised surfaces are masters of camouflaging dirt. We also call this the 'George Clooney of coating techniques: its look improves with age...

How to treat powder coated materials

Click here

Stainless steel 316

The highest stainless steel quality available is type AISI 316. Aggressive environmental conditions caused by chlorides, acid rain, salt and other rusty materials will require periodic maintenance.

Choose wisely

We advise a regular treatment with stainless steel cleaner or protector, especially in aggressive environments. Products to clean and protect are widely available.

How to treat stainless steel

Click here

Galvanized steel

Galvanization is the most durable method for protecting metal from rusting. The metal is immersed in a zinc bath, which results in a protective layer. If the layer gets damaged, the metal under it will start rusting. However, any damage can be touched up with zinc paint available from any DIY store. Galvanized steel has a very long life span and is perfectly recyclable if necessary.

Choose wisely

We call it the George Clooney of coating techniques: its looks improve better with age... Our tools with galvanized surfaces are masters of camouflaging dirt, thanks to the material's rough texture. At first, galvanized pieces look very shiny, but they will gradually turn matte under the influence of sun and rain. Rain may also cause dark stains underneath the connection zones.

How to treat galvanized steel

Click here

Colors

Off white (RAL9002)

Off white (RAL9002)

Black (RAL9005)

Black (RAL9005)

Copper brown (RAL8004)

Copper brown (RAL8004)

Galvanized steel

Galvanized steel

Beach beige (RAL1019)

Beach beige (RAL1019)

Off white (RAL9002)

Off white (RAL9002)

Black (RAL9005)

Black (RAL9005)

Copper brown (RAL8004)

Copper brown (RAL8004)

Hellwood

Hellwood

Beach beige (RAL1019)

Beach beige (RAL1019)

Off white (RAL9002)

Off white (RAL9002)

Black (RAL9005)

Black (RAL9005)

Copper brown (RAL8004)

Copper brown (RAL8004)

Beach beige (RAL1019)

Beach beige (RAL1019)

Stainless steel

Stainless steel

Galvanized steel

Galvanized steel

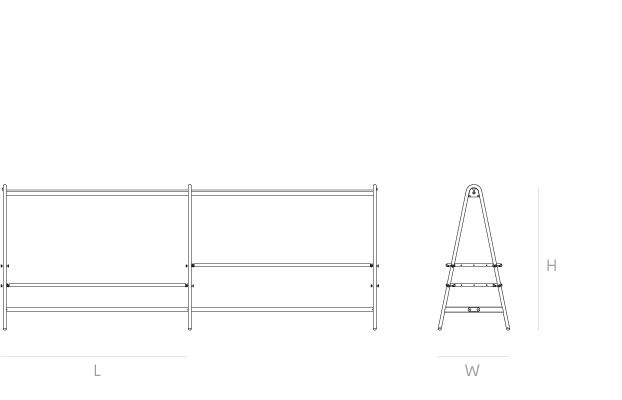

Dimensions

The Extension module is available in one dimension.